Overview

This machine is a continuous flow drying equipment used for drying sheet, strip, and granular materials with good breathability. It is particularly suitable for dehydrated vegetables, traditional Chinese medicine slices, and other materials with high moisture content and temperature not allowed to be high. This series of drying machines have the advantages of fast drying speed, high evaporation strength, and good product quality. For the paste like materials in the form of dehydrated filter cakes, they can also be dried after being granulated or made into rods.

Principle

The material is evenly laid on the mesh belt by the feeder, and the mesh belt is generally made of 12-60 mesh stainless steel wire mesh, which is dragged by the transmission device and moved inside the dryer. The dryer is composed of several units, each with independent circulation of hot air. Part of the exhaust gas is discharged by a dedicated wet fan, and the exhaust gas is controlled by a regulating valve. The hot air passes through the mesh belt covered with materials from bottom to top or from top to bottom to complete the process of heat and mass transfer, taking away the moisture of the materials. The mesh belt moves slowly, and the running speed can be automatically adjusted according to the material temperature. The dried finished product continuously falls into the feeder. The upper and lower circulation units can be flexibly equipped according to user needs, and the number of units can also be selected according to needs.

Application

Dehydrated vegetables, pellet feed, monosodium glutamate, coconut, organic pigments, synthetic rubber, polypropylene fiber, pharmaceuticals, medicinal herbs, small wood products, plastic products, aging and solidification of electronic raw materials.

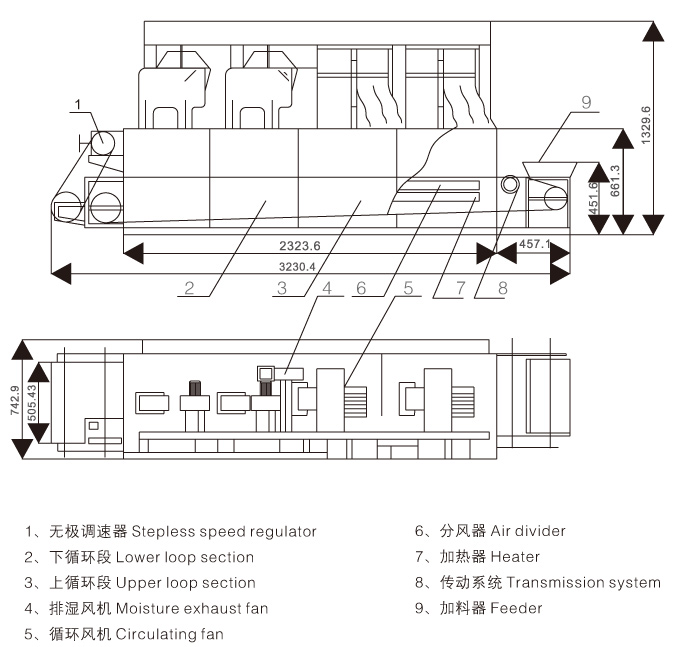

DWT type

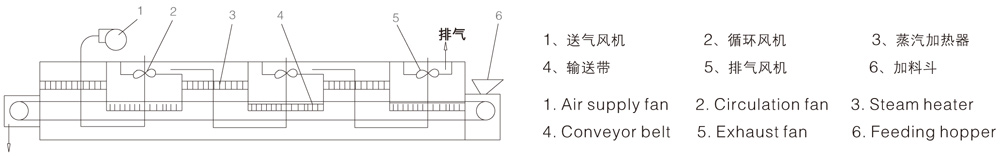

DW3-B type

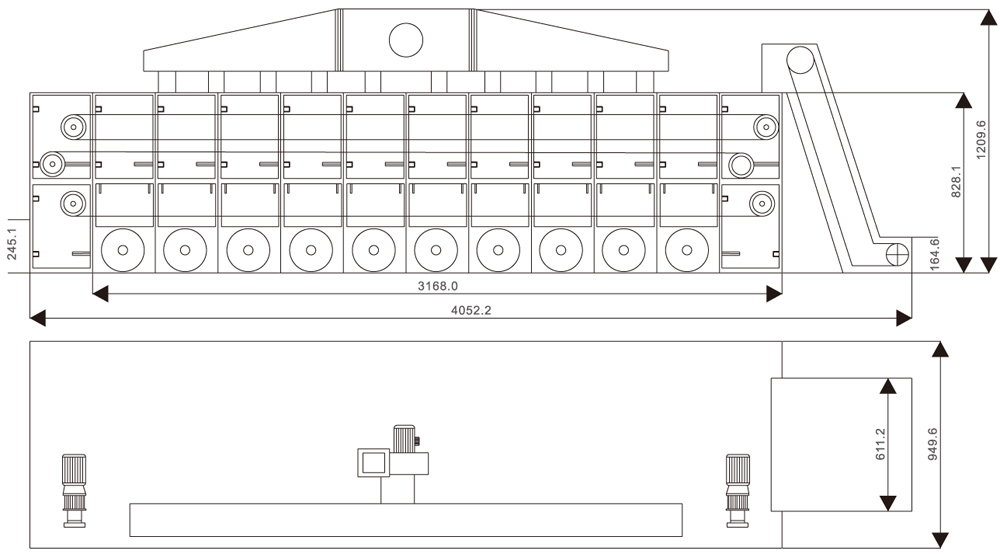

DW type

Model | DW-1.2-8 | DW-1.2-10 | DW-1.6-8 | DW-1.6-10 | DW-2-8 | DW-2-10 | |

Number of units | 4 | 5 | 4 | 5 | 4 | 5 | |

Bandwidth(Bo) | 1.2 | 1.6 | 2 | ||||

Drying section length(Ao) | 8 | 10 | 8 | 10 | 8 | 10 | |

Auxiliary material thickness(mm) | ≤60 | ||||||

Operating temperature(℃) | 50-140 | ||||||

Vapor pressure(MPa) | 0.2-0.6 | ||||||

Steam consumption(kg/h) | 120-300 | 150-375 | 150-375 | 170-470 | 180-500 | 255-600 | |

Drying time(h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | |

Dry strength (kg H?O/m2-h) | 6-20 | 6-20 | 6-20 | 6-20 | 6-20 | 6-20 | |

Number of fans | 5 | 6 | 5 | 6 | 5 | 6 | |

Total power of fan(kw) | 9.9 | 12.1 | 9.9 | 12.1 | 9.9 | 12.1 | |

Total power of equipment(kw) | 11.4 | 13.6 | 11.4 | 13.6 | 11.4 | 13.6 | |

Overall dimensions | A (mm) | 10.05 | 12.05 | 10.05 | 12.05 | 10.05 | 12.05 |

B (mm) | 1.5 | 1.5 | 1.91 | 1.5 | 1.5 | 1.5 | |

C (mm) | 3.15 | 3.15 | 3.15 | 3.15 | 3.15 | 3.15 | |

Weight(kg) | 4800 | 5780 | 5400 | 6550 | 6325 | 7800 | |

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.

DWT type

Model | DWT-Ⅰ | DWT-Ⅱ | DWT-Ⅲ | |

bandwidth(Bo) | 1.6 | |||

Drying section length(Ao) | 8 | 12 | 16 | |

Operating temperature(℃) | 50-140 | |||

Steam pressure(MPa) | 0.2-0.6 | |||

Heat Exchange Area (m2) | 300-500 | 400-600 | 500-800 | |

Drying time(h) | 0.2-1.2 | |||

Fan power(kw) | 0.75 | |||

Number of fans | 3 | 4 | 3 | |

Overall dimensions | Long L (m) | 10 | 14 | 18 |

Wide W (m) | 1.806 | 1.806 | 1.806 | |

High H (m) | 1.900 | 1.900 | 1.900 | |

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.

DW3-B type

Model | DW3-1.2-8B | DW3-1.2-10B | DW3-1.6-8B | DW3-1.6-10B | DW3-2-8B | DW3-2-10B | |

Number of units | 8 | 10 | 8 | 10 | 8 | 10 | |

Drying section length(Ao)(m) | 24 | 30 | 24 | 30 | 24 | 30 | |

Auxiliary material thickness(mm) | ≤60 | ||||||

Operating temperature(℃) | 50-140 | ||||||

Vapor pressure(MPa) | 0.2-0.6 | ||||||

Steam consumption(kg/h) | 240-550 | 300-750 | 300-750 | 340-950 | 350-1000 | 450-1000 | |

Drying time(h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | |

Dry strength(kg H?O/m2-h) | 6-20 | 6-20 | 6-20 | 6-20 | 6-20 | 6-20 | |

Total power of equipment(kw) | 21.7 | 26.1 | 21.7 | 27.2 | 29.2 | 35.2 | |

Overall dimensions | A (m) | 1.2 | 1.2 | 1.6 | 1.6 | 2.0 | 2.0 |

A1 (m) | 2.1 | 2.1 | 2.8 | 2.8 | 3.2 | 3.2 | |

B (m) | 8.0 | 10.0 | 8.0 | 10.0 | 8.0 | 10.0 | |

B1 (m) | 12.5 | 14.5 | 12.5 | 14.5 | 12.5 | 14.5 | |

C (m) | 3.5 | 3.5 | 3.5 | 3.5 | 3.6 | 3.6 | |

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.